- HOME

- Nessum Marketplace

- Nessum for HVAC

Innovative Communication Technology

Achieve long-distance, high-speed IP communication over existing wiring

Stay Ahead of Evolving Air Conditioning Control Needs

As IoT adoption grows in the HVAC and building control industries, the ability to build reliable, fast networks has become critical for business success. The cost-effective next-generation communication standard “Nessum” makes seamless device networking possible, even in large-scale facilities. It greatly simplifies data integration and high-precision device control, paving the way for the next generation of HVAC solutions.

Core Value for HVAC Manufacturers

High-precision energy management through faster communication over existing wiring

Effortlessly supports future service expansions and feature updates

Optimal for HVAC Systems Installed in These Facilities

Case Study:

Why Nessum is the Best Choice for HVAC Systems

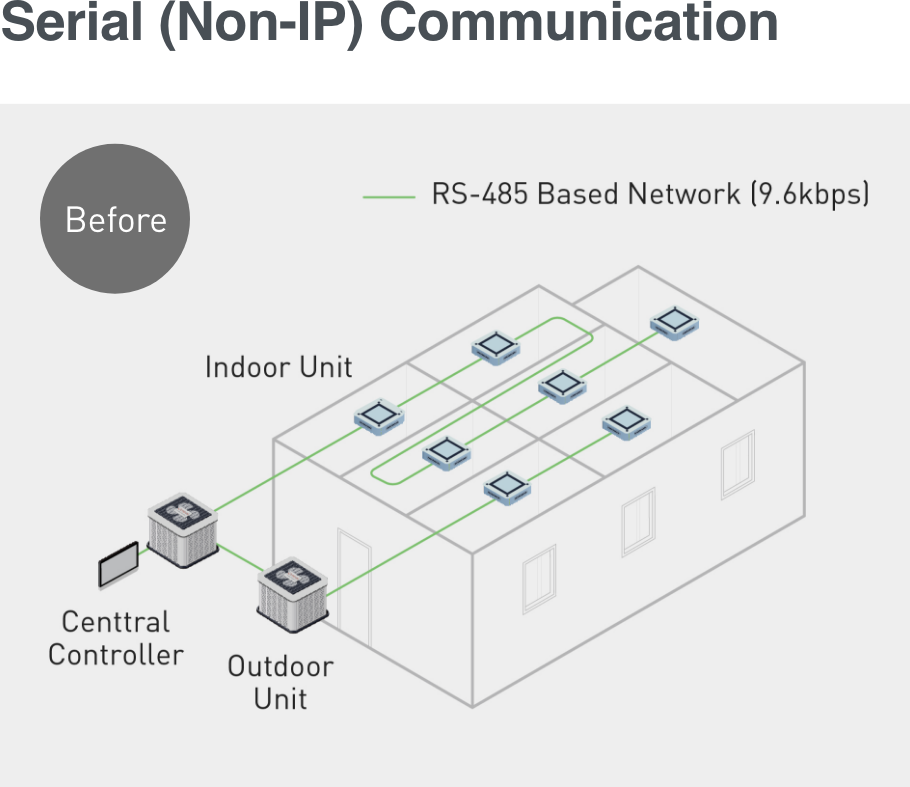

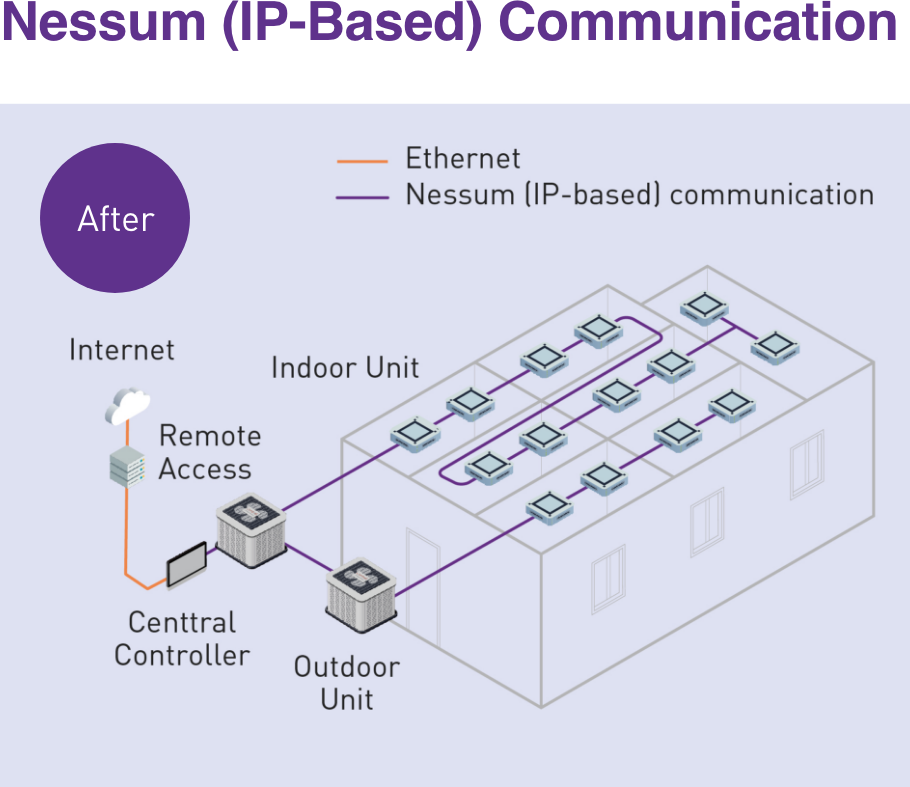

| Serial (Non-IP) Communication | Nessum (IP-Based) Communication |

| Communication Speed | |

| 9.6 kbps (low-speed communication) |

10 Mbps (high-speed communication) |

| Device Capacity | |

| Up to 64 devices (limit on device capacity) |

Up to 1,024 devices |

| Communication Type | |

| Non-IP communication (future expansion limited) |

IP communication (easy to expand functionality) |

| Reliability | |

| Susceptible to noise and interference | Resistant to noise and interference for stable communication |

| Communication Range | |

| Up to 100 meters when replacing with Ethernet (requires a HUB every 100 meters when extending range) |

Multi-hop function enables communication over several kilometers |

| Installation Cost | |

| Requires additional wiring and HUB costs when replacing with Ethernet | Low cost, as existing wiring does not need to be replaced |

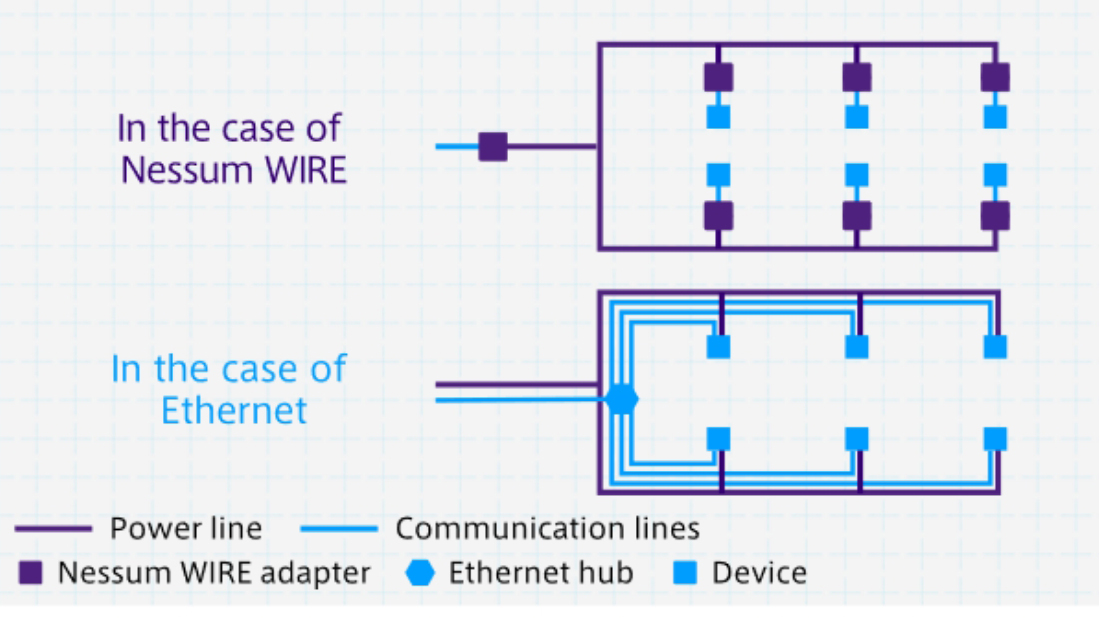

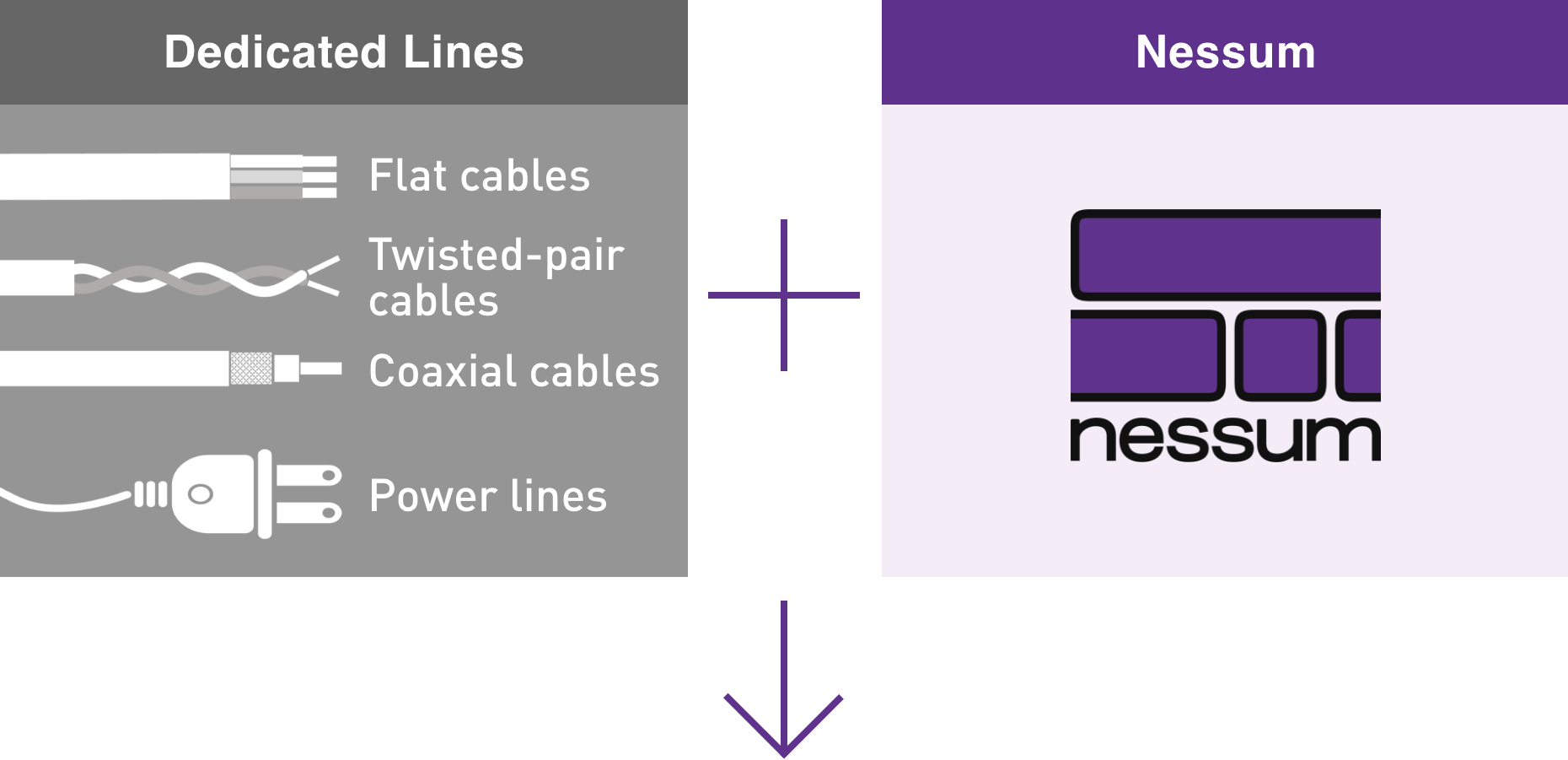

Transform Any Existing Wires into Communication Lines

There is wiring used for various purposes inside and outside buildings, such as dedicated lines, coaxial cables, and power lines. Nessum is compatible with the international standard IEEE 1901 series, enabling these existing wires to be transformed into communication lines. This eliminates the need for new communication cables, allowing networks to be constructed quickly and at a low cost.

- Works with a variety of existing wiring types

- Speeds up existing low-speed wired communication

- Supports long-distance coverage and IP conversion

Technical Features of Nessum

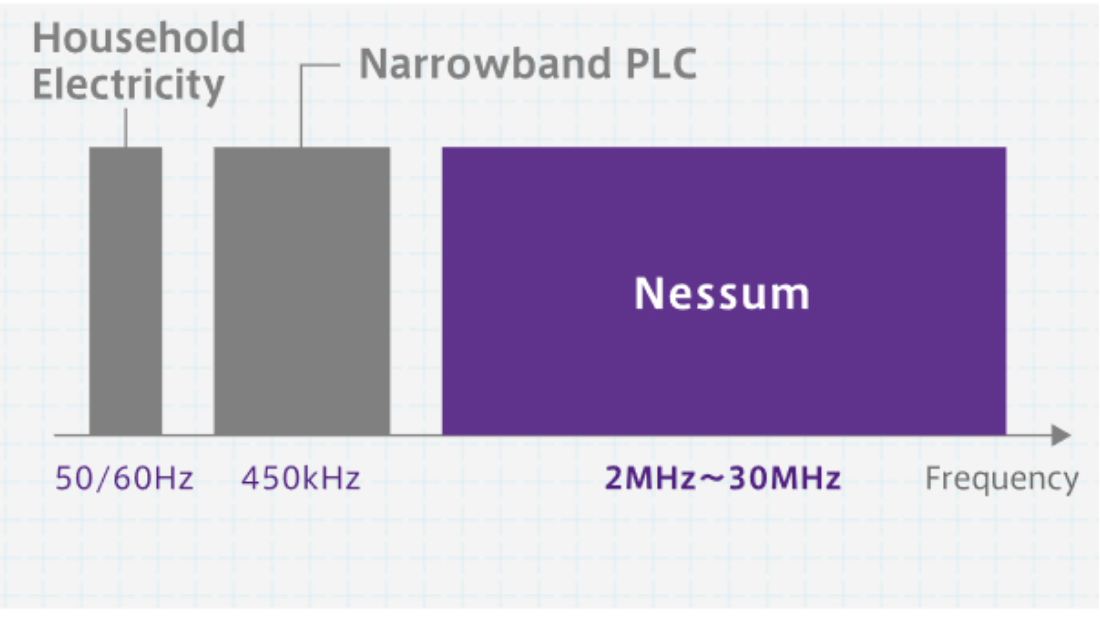

Speeding up existing low-speed wired communication

Mbps-based high-speed communication is possible

In preparation for the IoT era, there is a need to accelerate lines of communication such as RS485 Modbus, low-speed PLC, and HBS(IEBus). The introduction of Nessum will enable Mbps-based high-speed communication without changing these communication lines. This enables faster and more precise data integration and device control across HVAC systems.

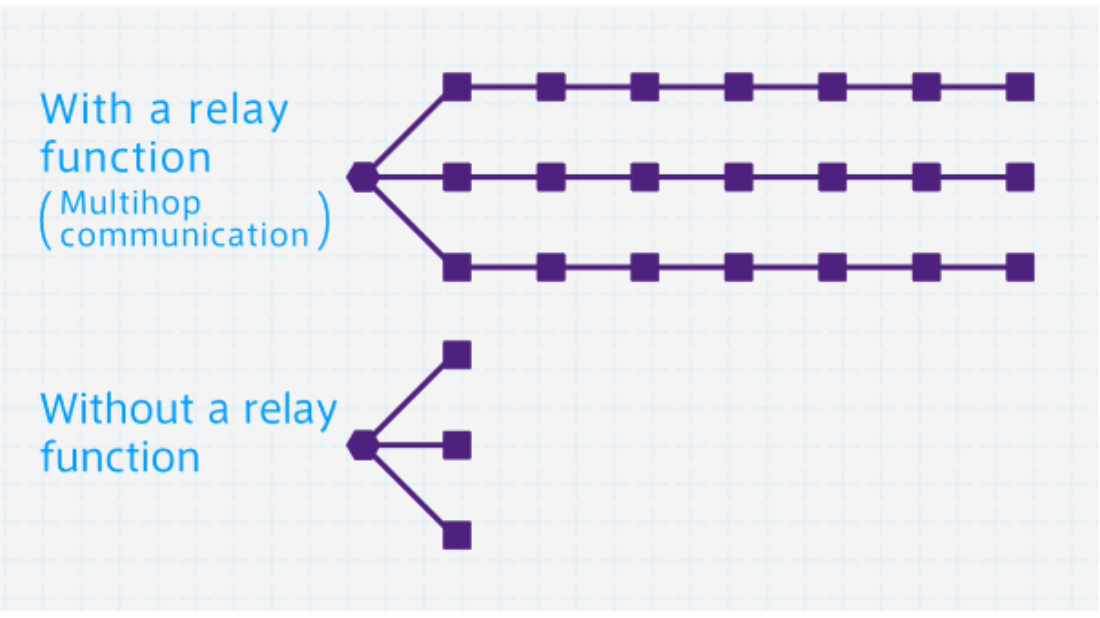

Long distance communication

Communication can be established over several kilometers

Even in large facilities such as buildings and factories, as well as with smart meters, the multi-hop technology that relays multiple subunits enables communication over several kilometers*. This ensures smooth connectivity and stable communication, even in large-scale facilities with widely distributed HVAC systems.

*The communication distance varies by use environment.

Simplified construction & low cost

A network can be built at a lower cost

The use of existing wiring (dedicated and power lines) saves the trouble of installing a new LAN cable. This will shorten the construction period and enable the establishment of a low-cost network. The ease of implementation also makes it easy for HVAC facility owners to adopt, ensuring a seamless integration process.