Case Study – Industrial

Challenges

Network construction for data collection of measuring instruments in factories

Solution

A retrofitted HD-PLC adopter(Powerline-to-Ethernet converter) that enables smart factory

Results

Low-cost network construction and operational efficiency

Digitization of measuring instrument data collection in factories

One company in Japan was manually reading data from factory instruments. This method is costly and prone to errors. To solve this, it is necessary to digitize the data collection of measuring instruments.

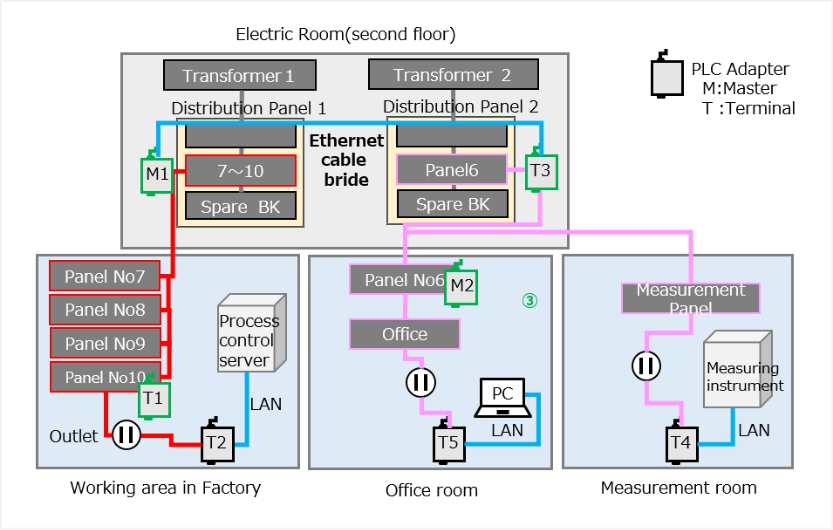

Specifically, it was necessary to connect the measuring instruments in the measurement room, the PC in the living room, and the server in the factory room via a network. The required speed is about TCP 1 Mbps.

Cost Issues for ethernet cable installation

This company first tried to construct an all-network with ethernet cables. However, due to the distance between the equipment, the cost requirement could not be met.

Network construction with reduced cost by HD-PLC

This issue has been resolved by the HD-PLC adapter(Powerline-to-Ethernet converter). This adapter can send and receive Ethernet signals over power lines. Connect this device to your PC, server, or instrument, and plug it into an electrical outlet near them. And in this case, we also installed some adapters on the distribution board because the distance between the devices is long. They act as signal repeaters.

With this support, it was possible to build a network at a low cost by using HD-PLC adapters without long ethernet cable installation. The actual man-hours required were 1 man-day for network design and 2 man-days for installation.

![[Past Event] Presenting Nessum Technologies to the World at AHR Expo 2026!](https://nessum.org/dcms_media/image/AHR-Expo-2026.png)