Smart Grid Case Study: How HD-PLC Allowed NuriFlex To Build A Faster & Cheaper Smart Metering Network

The global smart grid technology market is expected to reach $61 billion by 2023.

As more property developers and owners begin embracing smart grid and smart metering technology, one essential question arises — what is the best networking solution for these applications?

As the NuriFlex case study shows, this solution might just be HD-PLC.

In this article, we will:

- Define the smart grid technology and outline its basic principles

- Explore the key benefits that HD-PLC has in grid applications

- Present an overview of NURI Telecom and their project

- Navigate the challenges that the company faced with the project

- Summarize the results and takeaways of their application of HD-PLC in the project

What Is Smart Grid Technology?

The word “grid” in smart grid refers to an electrical grid or power grid — the infrastructure that helps transfer electricity from suppliers, such as power plants, to the end users — households and businesses.

By comparison, a smart grid is the evolution of the regular electricity supply grid that has two key characteristics:

- It enables the network to not only transfer electric power, but also digital data

- It allows for both data and electricity to travel in a two-way manner — from the supplier to the user and vice versa

Smart grids usually consist of three main systems:

- The infrastructure system is the hardware backbone of a grid network. It is comprised of the wiring and equipment necessary to enable the data and electricity transfer within the network. The components of the infrastructure system allow the operators of the network to monitor the flow of energy and data in the network in real time and adjust it according to the needs and capabilities of the specific application.

- The management system is a set of controls that allow for more precise and efficient energy management within a grid network. Its goal is to help improve and manage variables, such as cost, emissions, peak demand and the energy efficiency of a network.

- The protection system is what ensures the stability and security of a network. It protects the devices within the network from external interference and helps predict and prevent data loss and communication failures.

Smart grid is a broad term that generally refers to the electric power industry and large-scale applications.

However, it’s commonly used to denote smaller and more consumer-facing use cases — such as smart metering networks, which are among the most common applications of grid networking technology.

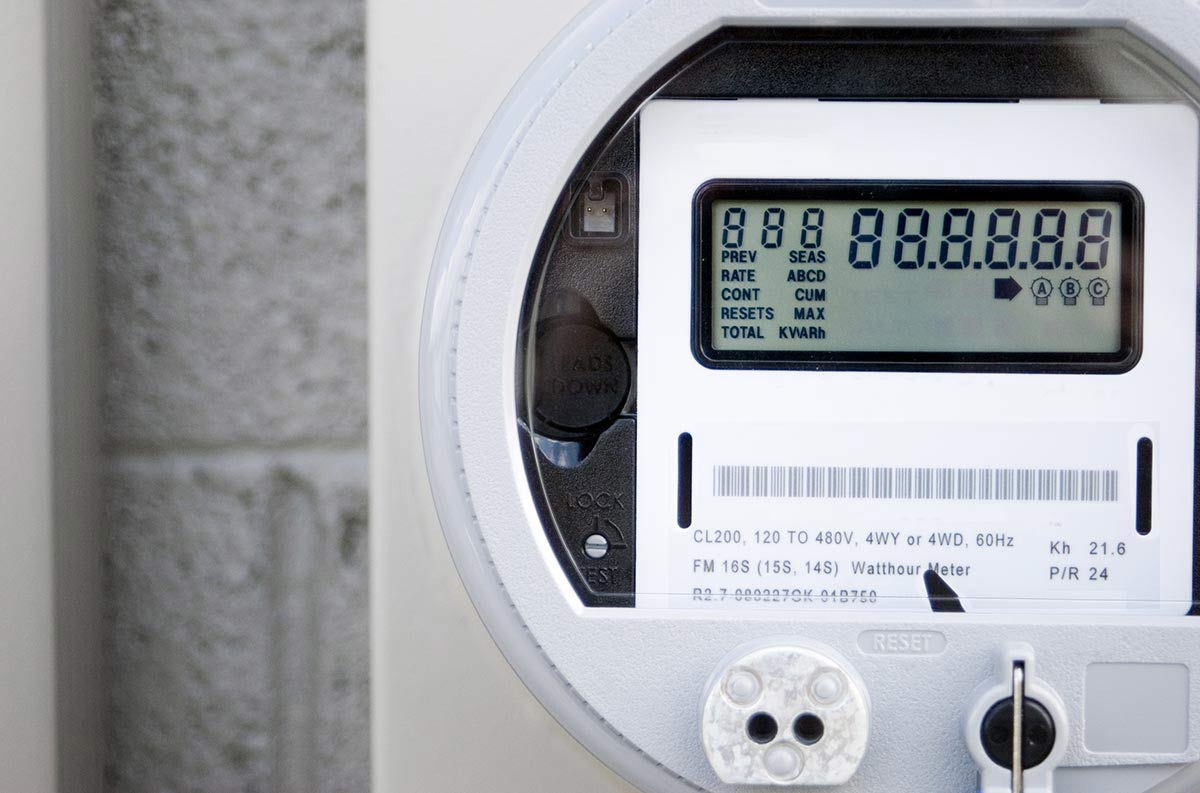

As the name suggests, a smart metering network consists of smart meters — devices that measure and transmit the consumption figures of utilities, such as electricity or water.

Following the principles of smart grid technology, smart meters can support two-way communication through the advanced metering infrastructure (AMI).

As a result, the devices within the smart meter network — which is commonly a part of a larger grid — can send information to the network operator through the electricity lines that power them.

Why HD-PLC Is Among The Best Smart Metering Network Solutions

The key idea behind the increasing adoption of smart grids is efficiency — both energy and operational.

Smart grids symbolize a more conscious approach to energy saving and smarter energy management. That’s precisely the reason why they are becoming so widely used in solar power plants and energy storage infrastructures.

At the same time, the networking solutions that are commonly used in such applications are often inefficient, in terms of the resources and labor that are required to build and maintain them.

In most residential buildings, commercial buildings and factories, the metering infrastructure is usually installed in secluded spaces, such as basements or external areas.

Connecting these areas to the wider network can be difficult and expensive.

For instance, wireless communication solutions are often not powerful enough to cover large areas or penetrate concrete walls. As a result, they require more precise planning and additional investments into signal repeaters — which adds to the overall cost.

These aspects are precisely where HD-PLC stands out as a promising solution for metering applications.

HD-PLC technology has several inherent advantages that help resolve the main challenges of grid connectivity:

- Lower cost: Unlike other wired solutions, HD-PLC does not require additional cabling to function and can operate with existing cables of almost any type: coaxial, twisted pair, copper, AC power lines and so on. As a result, smart meters can be connected to the wider grid via the same cables that are used to collect the consumption figures from the connected utilities. This means that building a metering network using HD-PLC does not require any additional investment into cabling.

- Wider range: One of the key innovations of HD-PLC is the Multi-hop functionality. In an HD-PLC Multi-hop network, each connection node can act as a signal extender or a repeater, effectively increasing the range, stability and capability of the network. Using HD-PLC Multi-hop, it is possible to build a grid that includes as many as 1,024 nodes and offers megabit connection speeds at distances of up to several kilometers.

- Higher connection speed: As mentioned previously, HD-PLC networks can boast data transmission rates of tens and hundreds of megabits per second, depending on the exact use case and network topology. In this aspect, HD-PLC is not only vastly superior to narrowband PLC solutions that are still commonly used in grid applications, but it also offers a better ratio of performance and cost, compared to conventional wired and wireless solutions.

- Powerful network recognition: Narrowband PLC solutions take as much as 1,800 second to recognize the network for the first time after being installed in the field application. As a result, building a network based on the narrowband PLC solution can be too time-consuming for the engineers who must install hundreds of meters in the field. By comparison, the HD-PLC standard features a network recognition speed of just under 60 seconds, making network installation a much more streamlined and efficient process.

- Fast data collection: The data collection interval of smart meter networks, built with narrowband PLC solution, is around 30 minutes. In other words, it takes around 30 minutes for such networks to collect, analyze and communicate the data. Such a considerable delay in communication might not be adequate in a sophisticated, demanding energy infrastructure that prioritized instant communication. HD-PLC is among the solutions that can support these requirements and help reduce the data collection interval to under 1 minute.

These are just a few of the benefits of HD-PLC that make it a prime solution for smart metering applications.

Now that we’ve covered the basics of smart metering and HD-PLC, let’s take a better look at NURI Telecom and their HD-PLC use case.

Smart Grid Case Study: NuriFlex Overview

Founded in 1992 in South Korea, NuriFlex is a global provider of energy IoT solutions that focus on the advanced metering infrastructure.

NuriFlex provides advanced metering infrastructure solutions to clients all over the world, who wish to replace their outdated metering systems with automated, smart metering networks.

A key innovation in NuriFlex’s approach to advanced metering infrastructure is the AiMiR Smart Grid platform. This platform helps adapt some of HD-PLC’s key features, such as Wavelet-OFDM modulation, for advanced metering infrastructure and automated meter reading (AMR) solutions.

The platform comes as a result of NURI Telecom’s commitment to HD-PLC technology. Prior to adopting HD-PLC, NURI mostly relied on low-frequency wireless and narrowband PLC solutions — more specifically, G3-PLC or Prime-PLC.

Those narrowband PLC are designed specifically for smart metering applications. However, this PLC standard quickly became insufficient once the metering technology became more common and smart metering devices became more sophisticated.

Over the course of the project reviewed in this case study, NuriFlex found out just how inefficient both narrowband PLC and wireless solutions can be for smart metering applications.

Explore NURIFlex products?

NURI Telecom’s Smart Metering Project Objectives & Challenges

NURI Telecom was approached by a Japanese client who commissioned the company to update the smart metering architecture across several apartment buildings.

NURI’s key objective for this project was to provide a networking solution that was:

- Cost-effective

- Easy to install and manage

- Relevant and future-proof enough to support the infrastructure’s evolution

- Fast enough to support the system’s stability and connectivity demands

However, apartment buildings are among the most challenging application cases when it comes to building an AMI.

The area that the network has to cover is vast, and the layout of the building can significantly hinder the performance of the network.

The client referred to in this case study had previously considered both wireless and wired solutions for their metering infrastructure.

However, deploying a wireless network proved to be costly and time-consuming, as it would require a lot of man-hours spent on monitoring and adjusting the signal strength.

On the other hand, implementing a narrowband PLC solution would not have been sufficient performance-wise for both the current and the future iteration of the metering system.

For instance, the G3-PLC protocol — even though it was developed with smart metering applications in mind — operates at kilobit speeds and kilohertz frequencies. As a result, its performance is hardly enough to support a sophisticated network of dozens of smart meters.

The limitations of both wireless and narrowband wired networks led NURI Telecom to turn to HD-PLC as the networking solution for the project.

HD-PLC Smart Grid Implementation — Results & Takeaways

NURI Telecom partnered up with MegaChips — another member of the HD-PLC Alliance — to develop an HD-PLC solution for their smart metering network.

The system was based around MegaChips’ MLKHN1501A system-on-a-chip HD-PLC adapter that supports Multi-hop functionality.

The key characteristics of the MegaChips solution used in the project include:

- Full IEEE 1901 compliance

- Bi-directional connectivity

- Ethernet/RS485 interface support

- 128Mbit SDRAM

- Maximum data transmission rate of 10Mbps at 10 hops

- CSMA/CA channel access

- Low power consumption

Apart from all of these benefits, the HD-PLC solution NURI Telecom chose for the project also featured a built-in mesh networking functionality which made the installation process effectively plug-and-play.

As a result, NURI Telecom was able to achieve the main objectives of the project, including:

- Reduced network complexity

- Improved connection stability

- Reduced deployment cost

![[Past Event] Presenting Nessum Technologies to the World at AHR Expo 2026!](https://nessum.org/dcms_media/image/AHR-Expo-2026.png)